The Brewery – Part 2 – The first time I made beer

After many hours…days…months of studying chemistry, materials, electronics and plumbing to properly design and build a machine that makes good beer consistently, I decided to go with a “basic design”.

By now I pretty much have the process down so I felt confident enough to write something about my experience.

Making the machine was hard but lots of fun. At times it was also really painful but in the end, it got done.

Revision 1.0

I googled around and found that people where using kegs as kettles because they are a cheap sources of high quality inox. Googled some more and found a cheap one, plus a used coil from a beer serving machine. Bought it, and it began…

Working the steel took some time because I had never cut or drilled trough inox. So I red about it, bought the tools and little by little, progress was being made…

Working the steel took some time because I had never cut or drilled trough inox. So I red about it, bought the tools and little by little, progress was being made…

Everything was really dirty so many hours where used to clean everything that would be in contact with the beer to a shine…

Everything was really dirty so many hours where used to clean everything that would be in contact with the beer to a shine…

…the metal was ready to be assembled into a machine.

…the metal was ready to be assembled into a machine.

Many parts had to be ordered, some from china to keep cost down, stalling the progress of hardware assembly…

Many parts had to be ordered, some from china to keep cost down, stalling the progress of hardware assembly…

…but eventually the revision 1.0 kettle was born.

…but eventually the revision 1.0 kettle was born.

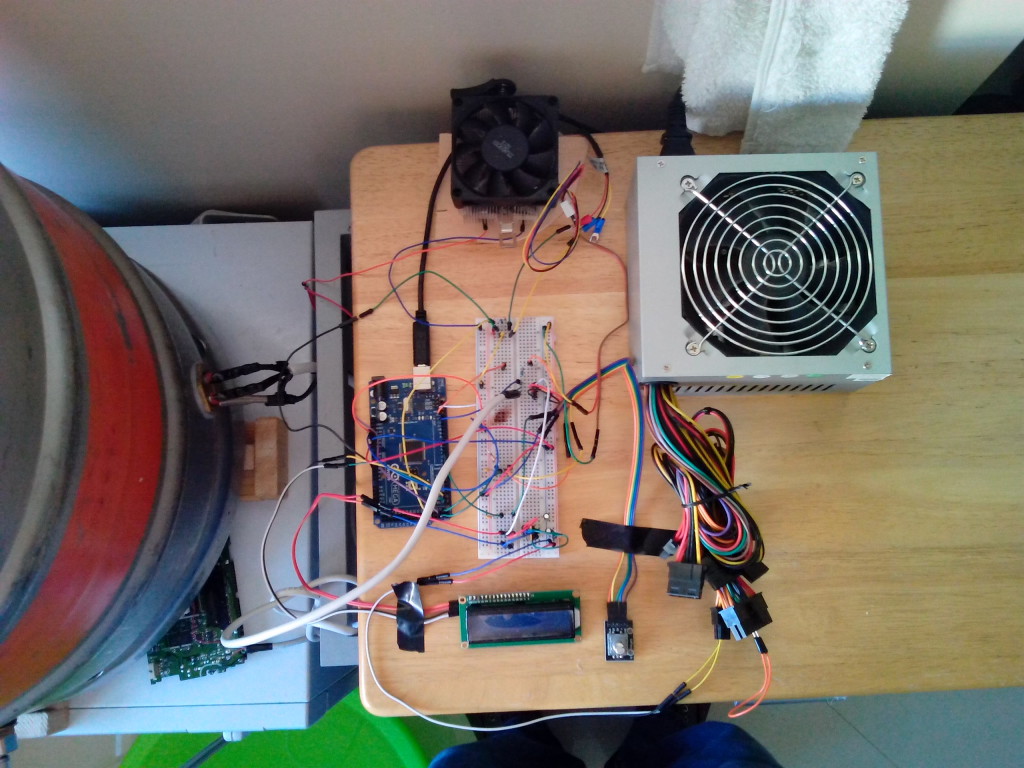

Meanwhile, the controller was starting to take shape at my desk. Temperature control was the first system I developed because at the time it seemed the easiest one to make progress on, keep motivation up.

Meanwhile, the controller was starting to take shape at my desk. Temperature control was the first system I developed because at the time it seemed the easiest one to make progress on, keep motivation up.

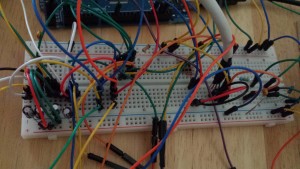

As time went by, while systems where being tested and included in the design, the controller test environment developed a “furryness”…

As time went by, while systems where being tested and included in the design, the controller test environment developed a “furryness”…

…that propagated wildly to it’s surroundings…

…that propagated wildly to it’s surroundings…

…as the controller was merging with the kettle.

…as the controller was merging with the kettle.

Around this time was when the first tests where being preformed. Temperature control with a PT100 was hard to figure out. (still is)

Revision 1.0 also had a magnetic mixer, which was awesome because I had to re-study electric motors and motor drivers. The mixer motor was embedded in a wooden stand I built for the machine so…cue the woodwork…

…some miss-engineering tools where involved when it was time to embed the spindle from the old CD-ROM drive into the stand…

…some miss-engineering tools where involved when it was time to embed the spindle from the old CD-ROM drive into the stand…

…I know ising a CD-ROM it’s a shortcut, but it was free.

…I know ising a CD-ROM it’s a shortcut, but it was free.

When this was done, the machine started taking shape and enough systems where operational to close a developing stage into a working prototype.

When this was done, the machine started taking shape and enough systems where operational to close a developing stage into a working prototype.

I present, Revision 1.0…

First Attempt

Like all first attempts, it failed. It failed mainly because the metal bucket that held the filtering bag with the crushed grain sat on top of the heating element, making it impossible for the grain to be completely submerged.

Now, looking at it, it’s quite obvious. At the time, this issue only came up when I went for it and tried to brew some beer for the first time.

Desperate, I went all or nothing, removing the bucket and placing all my faith in the PID’s temperature control over the heating element.

The PID held strong for a long time but a bug in the software stuck the heating element fully on, burning through the filtering bag and spreading an awful smell of burnt plastic and grain everywhere!

I did not document it but that basically was game over for Revision 1.

Revision 1.1

So Revision 1.1 was born!

The major development was the bending of all metal parts that where in the way of the bucket, solving the main issue.

Apart from that, the mixer got some covers and the electronics got put away into an old broken computer PSU.

Apart from that, the mixer got some covers and the electronics got put away into an old broken computer PSU.

…a big fan blowing on the SSR, now sitting on top of a huge aluminum heat sink, because the previous one decided to let out the magic smoke. The rat’s nest shield on top of the Arduino Mega is not my best work but it worked. A 24×2 character LCD display and a rotary encoder to browse the menu are embedded in the case for control. …and that’s it.

…and that’s it.

Second Attempt

And finally, this was the day I made beer for the first time.

…and this time everything went according to plan.

…and this time everything went according to plan.

Here it is after it got into the fermenter…

One day later I got confirmation the yeast was alive and fermenting. After the primary fermentation was over, the color and smell out the air-lock was indicating success.

One day later I got confirmation the yeast was alive and fermenting. After the primary fermentation was over, the color and smell out the air-lock was indicating success.

It fermented in the PET container for 4 weeks – a lot more than what I do now because that white stuff at the bottom should not be in contact with the beer after primary fermentation is over.

It fermented in the PET container for 4 weeks – a lot more than what I do now because that white stuff at the bottom should not be in contact with the beer after primary fermentation is over.

My first batches where all slowly forced carbonated using a Cornelius Keg and a CO2 cylinder, which is also not the way I do thing around here these days.

After the keg was cooled to 0ºC, for tasting, and I had confirmation the batch was good the entire keg was bottled.

After the keg was cooled to 0ºC, for tasting, and I had confirmation the batch was good the entire keg was bottled.

And that was the first time I brewed a successful batch with my machine.

What shall I do next?